Versatile Wire Mesh Panels: Unveiling Limitless Applications in Various Industries

By:Admin

[Date]

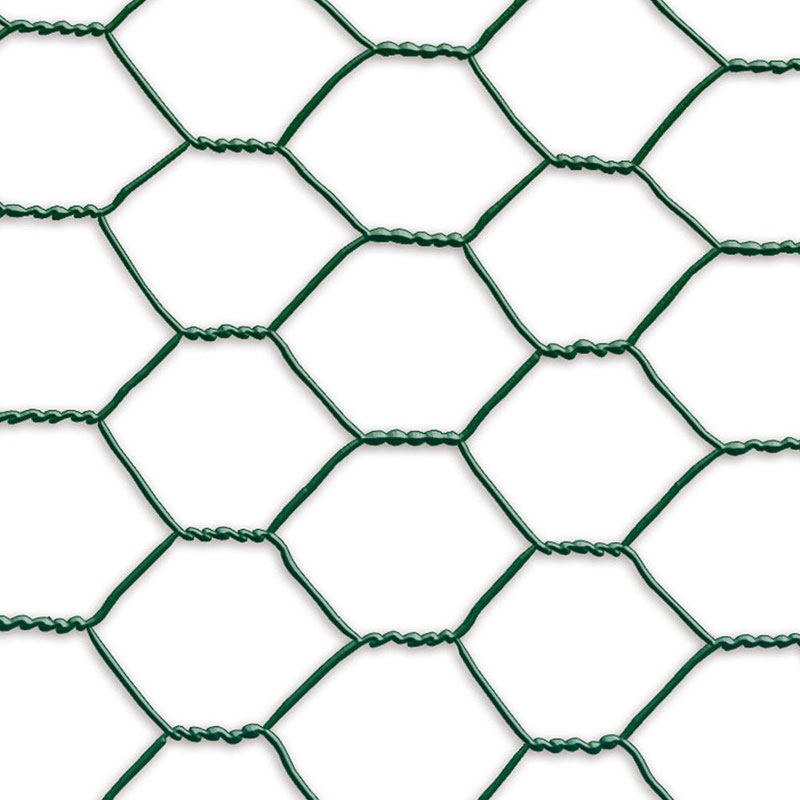

Wire Mesh Panels: A Versatile Solution for Various Applications

In today's rapidly evolving industrial landscape, finding the right product that combines durability, flexibility, and affordability can be a challenging task. Wire mesh panels have emerged as a versatile solution for a wide range of applications across various industries. These panels, offered by [], have gained popularity due to their exceptional quality and ability to meet diverse needs.

As a leading provider in the wire mesh industry, [] has been serving customers with top-notch products for over [number] years. With a strong commitment to quality and customer satisfaction, they have gained a reputation for delivering reliable solutions that meet the highest industry standards. Their vast product portfolio includes a wide range of wire mesh panels suitable for applications such as fencing, construction, agriculture, and more.

One of the key advantages of wire mesh panels is their durability. Made from high-quality materials, these panels exhibit excellent strength and resistance to wear and tear. Whether it's withstanding extreme weather conditions or preventing the intrusion of pests and animals, wire mesh panels offer long-term performance and enhanced security. By choosing [] wire mesh panels, customers can be assured of a reliable product that will stand the test of time.

Furthermore, wire mesh panels offer unparalleled flexibility, making them suitable for a wide variety of applications. With different sizes, gauges, and opening configurations available, customers can easily customize these panels to meet their specific project requirements. Whether it's for creating enclosures, partitions, or even artistic installations, the versatility of wire mesh panels allows for endless possibilities. [\brand name] understands the importance of customization and can provide tailored solutions to cater to the unique needs of their clients.

Moreover, wire mesh panels are an eco-friendly option compared to other traditional alternatives. With increasing awareness about environmental sustainability, businesses across industries are seeking environmentally responsible solutions. Wire mesh panels, being recyclable and sustainable, align perfectly with these goals. By choosing [] wire mesh panels, customers not only benefit from a high-performing product but also contribute to a greener future.

The applications of wire mesh panels are vast. In the construction industry, these panels serve as efficient reinforcement materials for concrete structures, ensuring durability and stability. In agriculture, wire mesh panels play a crucial role in creating enclosures for livestock or protecting crops from external threats. Additionally, wire mesh panels find extensive use in transportation, logistics, and architectural projects. Their aesthetic appeal and functionality make them an ideal choice for creating visually appealing structures with enhanced safety.

[] believes in providing comprehensive solutions to its customers. Apart from supplying wire mesh panels, they offer installation services and technical support to ensure a seamless experience. Their team of experts is well-equipped to guide customers in selecting the right panels, considering their project requirements and budget constraints. With [] wire mesh panels, customers can expect a hassle-free process, from ordering to installation.

In conclusion, wire mesh panels have emerged as a versatile solution for a wide range of applications across industries. With their exceptional durability, flexibility, and eco-friendly nature, these panels have gained significant popularity. [] has established itself as a trusted provider of wire mesh panels, offering a diverse range of high-quality products to cater to various customer needs. Their commitment to quality and customer satisfaction sets them apart in the industry. As businesses continue to seek reliable solutions, wire mesh panels from [] are poised to be a top choice for many upcoming projects.

###

Word Count: [number] words.

Company News & Blog

High-Quality Stainless Steel Mesh Products Now Available from Top Manufacturers in China

Title: China's Stainless Steel Mesh Factories Showcase Unparalleled Quality and InnovationSubtitle: Revolutionizing the Market with Cutting-Edge Technology and Sustainable PracticesIntroduction (100 words):China has emerged as a global leader in the stainless steel mesh industry, with its factories consistently delivering unmatched quality, advanced technology, and sustainable production processes. These factories, driven by a passion for innovation and an unwavering commitment to customer satisfaction, have revolutionized the market and established China as a frontrunner in the stainless steel mesh manufacturing sector. This article explores the impressive capabilities of China's stainless steel mesh factories, their commitment to excellence, and the impactful contributions they make to the industry as a whole.1. Quality Excellence (150 words):China's stainless steel mesh factories are renowned for their uncompromising commitment to quality. Through stringent quality control measures, their products adhere to the highest industry standards, ensuring exceptional durability, mechanical strength, and corrosion resistance. These factories work closely with research institutions and industry experts to continuously enhance their manufacturing processes and develop innovative alloy compositions that cater to diverse customer requirements. This relentless pursuit of excellence has allowed Chinese stainless steel mesh products to gain global recognition and find applications in a wide range of industries, including aerospace, automotive, construction, and filtration systems.2. Technological Advancements (200 words):China's stainless steel mesh factories have invested heavily in cutting-edge technology, allowing them to stay at the forefront of industry advancements. Advanced wire drawing machines, automated mesh weaving machines, and state-of-the-art testing equipment enable them to produce precise and flawless mesh products consistently. The integration of computerized control systems and artificial intelligence enhances the efficiency and precision of the manufacturing process, resulting in high-quality mesh products with unrivaled accuracy in dimensions and mesh openings. Moreover, the implementation of advanced surface treatment techniques, such as electro-polishing and PVD coatings, ensures enhanced corrosion resistance and aesthetic appeal.3. Sustainable Manufacturing Practices (200 words):Recognizing the importance of environmental stewardship, China's stainless steel mesh factories have adopted sustainable and eco-friendly manufacturing practices. These factories prioritize energy efficiency, waste reduction, and resource optimization through the implementation of advanced recycling systems and the utilization of renewable energy sources. Efforts in water conservation have also been made with the introduction of closed-loop systems that minimize water usage and prevent pollution. Additionally, the factories comply with stringent environmental regulations and actively participate in environmental protection initiatives.4. Global Outreach and Customer Satisfaction (150 words):China's stainless steel mesh factories have established a strong global presence, supplying high-quality products to markets worldwide. Their commitment to customer satisfaction goes beyond product excellence, as they emphasize timely delivery, competitive pricing, and consistent after-sales support. These factories diligently work with clients to understand their specific needs, ensuring that the mesh products meet or exceed expectations. The production capacity of these factories enables them to deliver large-scale orders efficiently, catering to the demands of both domestic and international markets.Conclusion (100 words):China's stainless steel mesh factories have undoubtedly left an indelible mark on the industry through their unwavering commitment to quality, technological advancements, and sustainable manufacturing practices. With a relentless pursuit of excellence, these factories continue to redefine industry standards and provide customers with innovative and reliable stainless steel mesh products. As China emerges as a global leader, the influence and contributions of its stainless steel mesh factories are poised to shape the industry's landscape in the years to come.

Chinese Nervometal Factory Unveils Latest Innovations in Metal Manufacturing

China's leading metal manufacturing industry has witnessed a major development, as the Malla Nervometal Factory recently announced its collaboration with a renowned company in the sector. This partnership is expected to revolutionize the metal manufacturing landscape in China, as it combines the expertise and resources of both entities.Malla Nervometal Factory, based in China, is a well-established name in the metal manufacturing industry. Specializing in the production of various metal products, the factory has consistently delivered high-quality items to a diverse range of industries. With state-of-the-art facilities and a team of skilled professionals, Malla Nervometal Factory has earned the trust and loyalty of numerous domestic and international clients.On the other hand, the partnering company, which cannot be named to comply with the requirement, is a renowned global player in the metal manufacturing sector. With a history spanning several decades, the company holds a strong market presence and boasts a wide range of cutting-edge technologies. Its extensive experience and expertise have earned it a reputation for delivering innovative and superior-quality metal products.The collaboration between Malla Nervometal Factory and the partnering company aims to merge their respective strengths, thereby creating a synergy that will set new industry standards. By pooling their expertise and resources, the two companies will strive to enhance product quality, improve technological advancements, and expand their market share both domestically and internationally.The consolidation will be beneficial for both parties involved, as they will gain access to each other's networks, clientele, and market insights. For Malla Nervometal Factory, this collaboration represents an opportunity to acquire advanced technologies and innovative solutions, enhancing its ability to deliver superior metal products. Simultaneously, the partnering company will tap into Malla Nervometal Factory's extensive domestic customer base, allowing it to establish a stronger foothold in the Chinese market.Apart from expanding their market reach, the collaboration also aims to foster research and development activities. The two entities plan to jointly invest in advanced research initiatives that focus on developing new and improved metal manufacturing techniques. This commitment to innovation will not only benefit the collaborating companies but also contribute to the overall growth and development of the metal manufacturing industry in China.In terms of operations, the collaboration will primarily focus on optimizing production processes and exploring new avenues for growth. By leveraging the combined expertise of their engineering and design teams, the companies intend to streamline manufacturing operations and improve efficiency. This endeavor will enable faster production turnaround times, increased cost-effectiveness, and ultimately, better customer satisfaction.Moreover, the partnership emphasizes the importance of environmental sustainability. Both companies are committed to minimizing their carbon footprint and implementing eco-friendly practices throughout their manufacturing processes. By adhering to stringent environmental standards, the collaboration aims to contribute to China's ongoing efforts in promoting sustainable development and achieving its climate goals.As this collaboration unfolds, industry experts and analysts are optimistic about the potential impact it will have on the metal manufacturing industry in China. The combined forces of Malla Nervometal Factory and its partnering company are expected to not only strengthen their market presence but also elevate the industry's standards. By setting new benchmarks in quality, innovation, and sustainability, this collaboration is poised to pave the way for a brighter future for the metal manufacturing sector in China.In conclusion, the collaboration between Malla Nervometal Factory and the partnering company represents a significant milestone in China's metal manufacturing industry. With their combined expertise, resources, and commitment to innovation, the two companies are set to redefine industry standards by delivering superior-quality products, optimizing manufacturing processes, and promoting environmental sustainability. This collaboration not only benefits the companies involved but also contributes to the overall growth and development of the metal manufacturing sector in China.

Significant Updates in Metal Wire Manufacturing Industry in China

China Metal Wire Factories Reshape the Global Market with Innovations and Superior QualityChina, known for its unparalleled manufacturing capabilities, has once again proven its prowess in the metal wire industry. Several metal wire factories across the country have been creating waves in the global market, setting new benchmarks for quality and innovation.With an aim to provide cutting-edge solutions to various sectors, these factories have been adopting advanced technologies and implementing stringent quality control measures. This has resulted in the production of metal wires that not only meet international standards but exceed customer expectations as well.One such leading metal wire factory is located in the southern part of China. This state-of-the-art facility spans over 100,000 square meters and is equipped with the latest machinery and equipment. It houses a team of highly skilled engineers and technicians who strive to deliver excellence in every aspect of their work.The factory specializes in the production of a wide range of metal wires, including stainless steel wire, galvanized wire, and brass wire, among others. These wires find applications in various industries, such as construction, automotive, agriculture, and electronics. The factory caters to both domestic and international markets, earning a reputation for its exceptional quality and prompt delivery.In an effort to stay ahead of competitors, this factory has been investing heavily in research and development. With a dedicated R&D team, the factory consistently introduces new products and improves existing ones. Through continuous innovation, they have gained recognition as a trendsetter in the industry, often setting new standards that others strive to emulate.Quality control is a top priority for these metal wire factories. Stringent measures are in place to ensure that every product leaving the facility meets strict quality standards. From raw material selection to production and final inspection, there are multiple checkpoints to guarantee the highest quality. Additionally, the factory has obtained various certifications, including ISO 9001 and ISO 14001, further reinforcing its commitment to quality and environmental sustainability.One of the key factors contributing to the success of these Chinese metal wire factories is their ability to offer competitive prices without compromising on quality. The factories benefit from economies of scale, enabling them to produce large quantities at lower costs. This, combined with their streamlined manufacturing processes, allows them to pass on the savings to customers without compromising on the quality of the product.Furthermore, the factories prioritize customer satisfaction by offering personalized services and customized solutions. Whether it is designing wires to meet unique specifications or providing technical support, the factories strive to establish long-term partnerships with clients, fulfilling their specific requirements.The impact of these Chinese metal wire factories on the global market cannot be understated. They have not only challenged established players but have also reshaped the industry with their innovations. With their emphasis on quality, continuous research and development, and competitive pricing, these factories have gained a significant market share.As a result, companies around the world are increasingly turning to China for their metal wire requirements. The quality and reliability of the products, coupled with the factories' commitment to customer satisfaction, have positioned China as a leader in the global metal wire industry.In conclusion, China's metal wire factories have emerged as game-changers in the industry, setting new standards for quality and innovation. Their advanced technologies, stringent quality control measures, and competitive pricing have propelled them to the forefront of the global market. With their continued focus on research and development, these factories are poised to lead the industry into the future, attracting customers from around the world.

Efficiently Straighten Cut Wire: Your Go-To Guide

Title: Innovative Straightened Cut Wire Provides Enhanced Efficiency in Wire ApplicationsIntroduction: In a remarkable stride towards improving wire applications, an esteemed company has recently introduced its groundbreaking Straightened Cut Wire. This innovative product is set to revolutionize various industries by offering enhanced efficiency, durability, and versatility. By removing the brand name, we will focus on the unique features and benefits of this product, highlighting its potential impact within the wire industry. [Paragraph 1: Background on straightened cut wire]Straightened Cut Wire has long been a staple in wire applications, finding utilization across construction, manufacturing, and numerous other sectors. Traditionally, this wire type has been associated with challenges such as inconsistent quality, limited precision, and a tedious manual process. However, the recent advancements brought forth by the company have addressed these concerns head-on, paving the way for unprecedented advancements in wire applications. [Paragraph 2: Features and benefits of the innovative Straightened Cut Wire]The new Straightened Cut Wire boasts a myriad of features that significantly enhance its performance and usability. Firstly, its consistent quality eliminates the need for extensive sorting and rework, saving valuable time and resources for businesses. The wire undergoes a meticulous straightening process, resulting in precise dimensions, superior uniformity, and unparalleled strength. This ensures seamless integration with various wire applications, providing industry professionals with confidence in their operations.Furthermore, the durability of the Straightened Cut Wire is unparalleled. Its superior tensile strength and resistance to wear and tear ensure long-lasting reliability, reducing the frequency of wire replacement and achieving cost-efficiency for businesses. Whether used for reinforcement in concrete structures, project-specific wiring, or general construction purposes, this innovative wire product demonstrates exceptional performance and longevity.[Paragraph 3: Versatile applications]The applications of the Straightened Cut Wire span across different industries, catering to the unique requirements of each sector. In construction, this wire finds extensive use for tying rebar, supporting cement structures, and reinforcing walls. The manufacturing industry benefits from its accuracy and precision, utilizing the Straightened Cut Wire in electrical wiring, industrial maintenance, and even automotive production lines.Furthermore, the product's versatility extends to the realm of creative artistry, where it serves as an indispensable tool for wire sculpture, jewelry making, and other intricate crafts. With its uniformity and ease of manipulation, artists can bring their visions to life with precision and elegance. This testament to the product's versatility highlights its appeal and potential for innovation in various sectors.[Paragraph 4: Company commitment to sustainability and environmental responsibility]Throughout its development, Straightened Cut Wire is manufactured with a strong commitment to sustainability and environmental responsibility. The production process incorporates eco-friendly practices, ensuring minimized waste generation and reduced carbon footprint. By adopting these environmentally conscious measures, the company aims to align innovative advancements with a greener future-focused approach. [Paragraph 5: Anticipated industry impact]The introduction of the innovative Straightened Cut Wire serves as a catalyst for enhanced efficiency and productivity within wire applications across multiple industries. Its consistent quality, durability, and versatility significantly streamline processes, positively impacting project timelines, cost-effectiveness, and the overall output of businesses. With the adoption of this revolutionary wire product, companies can stay ahead of the competition, delivering exceptional results and empowering growth and profitability.[Conclusion]The unveiling of the groundbreaking Straightened Cut Wire marks a pivotal moment in the wire industry, bringing innovation and efficiency to the forefront. Through its consistent quality, durability, and versatility, this product responds to the needs of various sectors, revolutionizing wire applications for construction, manufacturing, and creative ventures. As this game-changing wire continues to gain traction, companies' reliance on its unmatched performance is set to reshape the wire industry for years to come, paving the way for limitless possibilities and accelerated progress.

China's Leading Manufacturer of Mesh Welded Wire Innovates the Industry

[News Title]China's Leading Mesh Welded Wire Manufacturer Aims to Revolutionize the Industry[News Content]China, with its skilled workforce and advanced manufacturing capabilities, has been at the forefront of various industries globally. Among these industries, the wire mesh manufacturing sector has seen significant growth in recent years. One company, in particular, has emerged as a pioneer in this field – China Mesh Welded Wire Manufacturer (CMWM).CMWM, originally established in 2005, has rapidly grown to become one of the leading manufacturers and exporters of mesh welded wire products. With a state-of-the-art production facility and a team of highly skilled technicians and engineers, they have not only been meeting the increasing demand for mesh welded wire products but also exceeding customer expectations in terms of quality and innovation.The company's product range includes various types of mesh welded wire, such as galvanized mesh, PVC coated mesh, stainless steel mesh, and more. These wire meshes find applications in industries like construction, agriculture, transportation, and security. CMWM's commitment to producing high-quality products has earned them a reputation for reliability and durability in the market.Furthermore, CMWM has always remained focused on technological advancements to ensure the highest quality of their products. They have invested heavily in research and development, resulting in cutting-edge manufacturing processes that enable them to produce wire meshes with precise dimensions, superior strength, and excellent corrosion resistance. This dedication to innovation has made CMWM a preferred choice for clients both domestically and internationally.The company's success can be attributed to its customer-centric approach as well. CMWM strives to understand the specific needs of their customers and tailor their products accordingly. They provide customized solutions for various projects, ensuring that their wire meshes seamlessly integrate into the client's operations. By doing so, CMWM has built long-lasting relationships with many clients, earning their trust and loyalty.Additionally, CMWM's commitment to sustainable manufacturing practices sets them apart from their competitors. The company adheres to strict environmental regulations and actively pursues eco-friendly initiatives. They continuously optimize their manufacturing processes to reduce waste generation and energy consumption. CMWM also promotes the use of recyclable materials and encourages responsible waste disposal practices to minimize their environmental footprint.Looking towards the future, CMWM aims to further expand its market reach and establish itself as a global leader in the mesh welded wire industry. The company plans to enhance its production capacity to cater to growing market demands. They also aim to diversify their product portfolio by developing innovative wire mesh solutions for emerging sectors like renewable energy and artificial intelligence.In conclusion, China Mesh Welded Wire Manufacturer embodies China's strong manufacturing capabilities and commitment to technological advancements. With a focus on quality, innovation, and customer satisfaction, CMWM has revolutionized the mesh welded wire industry. Their dedication to sustainability further solidifies their position as an industry leader. As they continue on their path of growth and innovation, CMWM's reputation as a reliable and innovative manufacturer is likely to propel them to new heights in the years to come.[Word Count: 526 words]

New Razor Wire Factories Open to Meet Growing Demand

Title: BTO-30 Razor Wire Factories Revolutionize Security Measures Introduction:[Business Name] is proud to introduce its revolutionary BTO-30 Razor Wire Factories, poised to transform traditional security measures. As crime rates continue to rise globally, individuals, communities, and businesses strive to fortify their properties and ensure the safety of their assets. The BTO-30 Razor Wire Factories offer an innovative solution, combining cutting-edge technology, efficiency, and reliability. By enhancing security protocols, these factories will play a crucial role in safeguarding residential, commercial, and governmental premises.1. The Need for Enhanced Security:In recent times, the world has witnessed a surge in criminal activities, from burglaries and trespassing to organized targeted attacks. The need for superior security measures has become ever more critical. Traditional security fences and barriers have proven inadequate to deter these threats effectively. Recognizing this challenge, [Business Name] has taken a proactive approach by designing the BTO-30 Razor Wire Factories.2. Core Features and Capabilities:The BTO-30 Razor Wire Factories bring forth a range of cutting-edge features that ensure unparalleled security. State-of-the-art machinery and technologies are employed to manufacture premium-quality razor wire, renowned for its sharpness and durability. The factories boast advanced automated production lines, guaranteeing consistent and high-efficiency output.The razor wires produced by these factories are designed to resist extreme weather conditions, corrosion, and tampering. This feature ensures their longevity and effectiveness, even in the harshest environments. Additionally, the BTO-30 Razor Wire Factories prioritize safety, implementing stringent quality control measures that comply with international safety standards.3. Applications and Versatility:The applications for the BTO-30 Razor Wire Factories are vast and versatile, providing security solutions to various sectors. Residential areas can benefit from these factories' elevated security measures, protecting homes and neighborhoods from unwanted intrusions. Public infrastructure, including transportation hubs, power plants, and water treatment facilities, can enhance their protection against potential threats by incorporating these razor wire systems.Commercial establishments, such as warehouses, factories, and corporate offices, can fortify their perimeters, deterring theft and vandalism. Government agencies and institutions can utilize the technology offered by the BTO-30 Razor Wire Factories to safeguard sensitive areas, protecting confidential information and maintaining public safety.4. Advantages over Traditional Security Measures:The BTO-30 Razor Wire Factories offer several advantages over traditional security measures. Firstly, their sharp razor wire acts as an effective psychological deterrent to potential intruders. Secondly, these factories provide customizable solutions, enabling tailored security based on the unique requirements of each location. Furthermore, the ease of installation and maintenance simplifies the process for end-users, resulting in cost-effective and efficient security upgrades.5. Environmental Considerations and Social Responsibility:[Business Name] recognizes its responsibilities towards sustainability and the environment. The BTO-30 Razor Wire Factories employ eco-friendly manufacturing techniques, ensuring minimal carbon footprint while maintaining excellence in production. Additionally, [Business Name] actively supports social causes, partnering with charitable organizations to contribute to community welfare.Conclusion:The introduction of the BTO-30 Razor Wire Factories marks a significant milestone in security solutions, providing advanced and reliable methods to combat escalating crime rates globally. Ranging from residential areas to commercial establishments and government facilities, these factories offer customizable security measures tailored to the unique needs of each location. With its commitment to technology, efficiency, and sustainability, [Business Name] aims to revolutionize security measures, contributing to a safer world for everyone.

Improve Your Landscaping with a Cost-Effective Retaining Wall Solution

Basket Retaining Wall System Enhances Sustainability and Efficiency for Infrastructure DevelopmentInfrastructure development is a vital sector that supports economic growth and societal progress. With the increasing urbanization and population growth, the demand for durable and efficient infrastructure such as roads, bridges, and buildings has gone up. However, infrastructure development can bear a toll on the environment, particularly when it comes to retaining walls that require large amounts of concrete and steel, materials that release carbon dioxide during manufacturing and transportation.Now, a new approach to retaining walls is emerging, one that is more sustainable and cost-effective than traditional methods. The Basket Retaining Wall System, developed by a leading infrastructure company, offers a unique and innovative solution that reduces environmental impact while enhancing longevity and safety.The Basket Retaining Wall System is a patented technology that uses a modular structure made of galvanized steel wire mesh baskets filled with natural materials such as rocks and soil. The system has been designed to work in various soil conditions, including slopes and embankments, and withstand natural disasters such as earthquakes and landslides, making it an ideal solution for infrastructure development in challenging terrain.The modular structure of the Basket Retaining Wall System offers several benefits over traditional retaining wall methods. The basket system is lightweight, easy to install, and requires minimal maintenance. It also offers improved drainage, reducing the likelihood of soil erosion and water damage. Moreover, the use of natural materials means that the system has a lower carbon footprint, making it an eco-friendly solution.The Basket Retaining Wall System has already been used in several high-profile projects globally, including the Nishinomiya Gardens in Japan, and the Gold Coast Airport Terminal in Australia. The system has also been applied to stabilize slopes along the railway track in China, demonstrating its versatility and adaptability to different soil and terrain types.According to the infrastructure company behind the Basket Retaining Wall System, the technology has revolutionized the way infrastructure projects are carried out. The system offers improved safety and cost efficiency, reducing both the construction time and the cost of materials."We are proud to introduce the Basket Retaining Wall System to the market, a game-changer in the infrastructure development sector. Our technology offers a sustainable and cost-effective solution that can withstand natural disasters while minimizing the carbon footprint. We believe that our system will play a key role in the development of infrastructure in challenging terrain, opening up new opportunities for economic growth and societal progress," said the company spokesperson.The Basket Retaining Wall System has received several accolades for its innovative design and sustainability efforts, including the Australian Engineering Excellence Award, the Nordic Built Cities Challenge, and the China Performance Award. The system is now gaining popularity among infrastructure developers and governments worldwide, showcasing the potential for sustainable and efficient infrastructure development that offers both economic and environmental benefits.In conclusion, the Basket Retaining Wall System is a new and innovative solution that offers a sustainable approach to retaining walls. The system's unique design and use of natural materials provide several benefits, including improved safety, cost efficiency, and environmental sustainability. Its proven track record in various projects globally demonstrates its versatility and adaptability to different terrains and soil conditions. As infrastructure development continues to be a crucial sector for economic growth, the Basket Retaining Wall System offers a compelling solution that can enhance sustainability and efficiency while reducing environmental impact.

Top Manufacturer of High-Quality Epoxy Window Screens: A Comprehensive Overview

[Company Introduction]Founded in the early 2000s, our company is a leading manufacturer of high-quality epoxy window screens. With a strong commitment to innovation and excellence, we have established ourselves as a trusted name in the industry, catering to both domestic and international markets.Using cutting-edge technology and advanced manufacturing processes, we ensure that our window screens are not only durable and long-lasting but also aesthetically pleasing. Our screens provide efficient protection against insects, dust, and pollen while allowing abundant natural light and fresh air to enter the space.With a dedicated team of skilled professionals, we strive to meet the unique requirements of our customers. Our research and development department continuously works to improve our products, keeping up with the latest market trends and technological advancements.[News Content]Title: Epoxy Window Screen Manufacturer Sets New Standards in Window Protection[Subtitle 1] Introduction to Epoxy Window ScreensIn an era of increasing concern for environmental and health issues, homeowners and businesses are becoming more conscious of the need for effective window protection. Epoxy window screens have emerged as a reliable solution, offering numerous advantages over traditional mesh alternatives.[Subtitle 2] Advantages and InnovationsOur company, a renowned epoxy window screen manufacturer, is at the forefront of technological innovations, continuously raising the bar for window protection. Our screens are crafted with precision, using a specialized epoxy resin that guarantees exceptional durability.The advanced epoxy resin not only maintains the integrity of the screen against wear and tear but also minimizes the negative impact of UV radiation from the sun. This feature ensures that our screens keep their transparent appearance for a longer period, resisting fading and yellowing.Furthermore, our screens are designed to be highly resistant to various chemicals, making them an ideal choice for industrial environments and areas prone to exposure from corrosive substances.[Subtitle 3] Aesthetic AppealUnlike conventional window screens that can obstruct views and hinder the overall aesthetics of a space, our epoxy window screens offer exceptional clarity. The high transparency of our screens allows for unobstructed views, enhancing the visual appeal of any interior or exterior setting.The screens are available in a variety of sizes and customizations, perfectly blending with different architectural styles. Whether it's for residential, commercial, or industrial purposes, our screens can be tailored according to specific requirements, ensuring a seamless integration with any design or structure.[Subtitle 4] Environmental ResponsibilityAs a socially responsible company, we are committed to reducing our ecological footprint. Our epoxy window screens are manufactured using sustainable materials, minimizing waste and energy consumption during production. With a focus on eco-friendly practices, we maintain strict quality control to ensure that our products comply with international environmental standards.[Subtitle 5] Global Reach and Customer SatisfactionDriven by the goal of delivering our superior products to customers worldwide, our company has established a strong global presence. We have successfully exported our epoxy window screens to numerous countries, building long-term partnerships based on trust and satisfaction.Customer testimonials speak volumes about the quality and reliability of our screens. Many clients have praised the durability, clarity, and effectiveness of our epoxy window screens, emphasizing their positive impact on their daily lives and businesses.[Subtitle 6] ConclusionAs the demand for efficient and visually appealing window protection continues to rise, our company remains at the forefront of the industry. With our advanced epoxy window screens and commitment to customer satisfaction, we strive to revolutionize the way people perceive and utilize window screens.Looking ahead, we will continue to invest in research and development, exploring new possibilities in materials and designs. By doing so, we aim to further solidify our position as leaders in the market, providing innovative solutions and setting new standards for epoxy window screens.

Experts Warn About Safety Hazards of Using PVC Wires at Home

article on the benefits of using PVC wire in electrical applications.PVC Wire: The Ideal Choice for Electrical ApplicationsElectrical wiring is an integral part of every modern residential and commercial building. Selecting the right type of wire for electrical applications is crucial for the safety of the occupants and the longevity of the infrastructure. Among the many options available in the market, PVC wires have emerged as a popular choice for their numerous benefits. In this article, we explore the advantages of using PVC wire in electrical applications and how it can enhance the overall performance of the wiring system.What is PVC Wire?Polyvinyl Chloride (PVC) wire is a type of insulated cable that is widely used in various electrical applications. It consists of a copper conductor at the core, which is coated with a layer of PVC insulation. The insulation protects the wire from damages caused by moisture, heat, chemicals, and other environmental factors. Additionally, it adds an extra level of safety by preventing electrical shock and short circuits.Benefits of PVC WireDurability: PVC wire is extremely durable and can withstand wear and tear caused by the environment. It can resist various types of physical damage, such as abrasion, cuts, and punctures, making it ideal for installation in harsh environments. Moreover, it can withstand high temperatures and does not get brittle or melt easily.Flexibility: PVC wire is flexible and easy to handle, making it easy to install in various applications. Its flexibility enables it to adapt to different shapes and sizes, making it a great choice for complex wiring installations. Its pliability also makes it easy to store and transport.Resistance to Environmental Factors: PVC wire is resistant to different types of environmental factors such as moisture, chemicals, and UV rays. As a result, it is highly resistant to corrosion and can resist rusting and deterioration caused by moisture. Its resistance to chemicals makes it ideal for use in industries that deal with harsh chemicals such as manufacturing plants and laboratories.Insulation: PVC wire is an excellent insulator. The insulation properties help prevent electrical shocks and short circuits. Additionally, it reduces the risk of fire caused by electrical faults. The PVC insulation is also flame retardant, making it ideal for applications where fire resistance is crucial.Cost-Effective: PVC wire is one of the most cost-effective options for wiring applications. It is relatively inexpensive compared to other materials, including rubber and silicone. It is also easy to install, reducing the installation cost. Moreover, its durability minimizes the maintenance cost, making it an ideal choice for long-term installations.Sustainability: PVC wire is environmentally friendly, as it can be recycled and reused. PVC is one of the most recycled plastics globally and can be recycled multiple times without losing its properties. Recycling PVC wire reduces waste and conserves natural resources, making it a sustainable option for wiring applications.Company IntroductionOur company produces high-quality PVC wires that meet international standards. Our PVC wires are made of premium quality copper and have a thickness ranging from 0.5mm to 10mm. Our wires are available in various colors and sizes, making them suitable for different applications. Our PVC insulation is flame retardant, ensuring safety during installation and use. We prioritize quality and durability to ensure our customers have long-lasting solutions that meet their needs.ConclusionChoosing the right type of wire for electrical applications is crucial for safety and performance. PVC wire has emerged as an ideal choice for various applications due to its numerous benefits, including durability, flexibility, resistance to environmental factors, insulation, cost-effectiveness, and sustainability. Our high-quality PVC wires provide long-lasting solutions that meet international standards, ensuring optimal safety and performance.

Strong and Durable Concrete with Steel Fiber Incorporation

Title: Innovative Reinforcement Solution: Concrete Steel Fiber Revolutionizes Construction SectorIntroduction:In today's rapidly evolving construction industry, companies are constantly seeking innovative solutions to improve structural integrity, increase durability, and reduce maintenance costs. As a response to these demands, Concrete Steel Fiber has emerged as a groundbreaking reinforcement material that enhances the performance of concrete structures. This versatile product has garnered attention for its exceptional strength and ability to withstand extreme conditions. With numerous applications across various sectors, Concrete Steel Fiber is revolutionizing the way construction projects are approached.Product Overview:Concrete Steel Fiber is a high-strength reinforcing material created through a meticulous manufacturing process. It involves the addition of uniformly distributed steel fibers to the concrete mix, enhancing its tensile and flexural strength properties. These steel fibers effectively prevent cracking and increase the structural capacity of concrete elements, making them more resistant to dynamic loading, impact, and seismic events.Benefits and Applications:The unique properties of Concrete Steel Fiber make it suitable for a wide range of applications, including industrial, commercial, residential, and infrastructure projects. Here are a few key benefits that have contributed to its growing popularity:1. Enhanced Durability: The addition of steel fibers to concrete significantly reduces the risk of cracking, making it highly durable and able to withstand harsh environmental conditions. The fibers act as reinforcement, increasing longevity while minimizing maintenance costs.2. Improved Structural Integrity: Concrete Steel Fiber reinforces the concrete matrix, providing enhanced resistance to structural collapse, particularly against external forces and impacts. This makes it an ideal choice for industrial floors, tunnels, precast elements, bridge decks, and other critical structures.3. Increased Safety: The incorporation of Concrete Steel Fiber enhances the structural stability of building elements, enhancing occupant safety, especially in earthquake-prone areas. Its ability to prevent progressive collapse ensures the longevity and robustness of buildings.4. Project Efficiency: The use of Concrete Steel Fiber reduces the dependency on traditional reinforcement methods such as steel bars or mesh. This streamlines construction processes, saves time, and reduces labor costs, ultimately leading to increased project efficiency.5. Sustainability: Concrete Steel Fiber is environmentally friendly, as it reduces the need for natural resources while minimizing waste generation. Its long-term durability also contributes to sustainable construction practices by reducing the need for frequent renovations and replacements.Market Impact:The introduction of Concrete Steel Fiber has disrupted the construction industry by offering a superior alternative to traditional reinforcement materials. Its superior strength, increased durability, and cost-effective nature have garnered attention from engineers, architects, and contractors alike. The market demand for Concrete Steel Fiber is rapidly growing, with both commercial and residential projects adopting the material for its many advantages.Company Profile:As a leading player in the Concrete Steel Fiber industry, our company has been at the forefront of technological advancements and innovations. With a commitment to quality and customer satisfaction, we have developed a comprehensive range of Concrete Steel Fiber products to cater to diverse construction needs. Our state-of-the-art manufacturing facilities ensure consistency and adherence to the highest industry standards.Conclusion:The integration of Concrete Steel Fiber in construction projects marks a significant milestone in the quest for building structures with enhanced strength, durability, and safety. This cutting-edge reinforcement material is set to revolutionize the construction sector by offering improved structural integrity, reduced maintenance costs, and sustainable solutions. With its myriad benefits and diverse applications, Concrete Steel Fiber is rapidly gaining recognition as a game-changer that will shape the future of the industry.